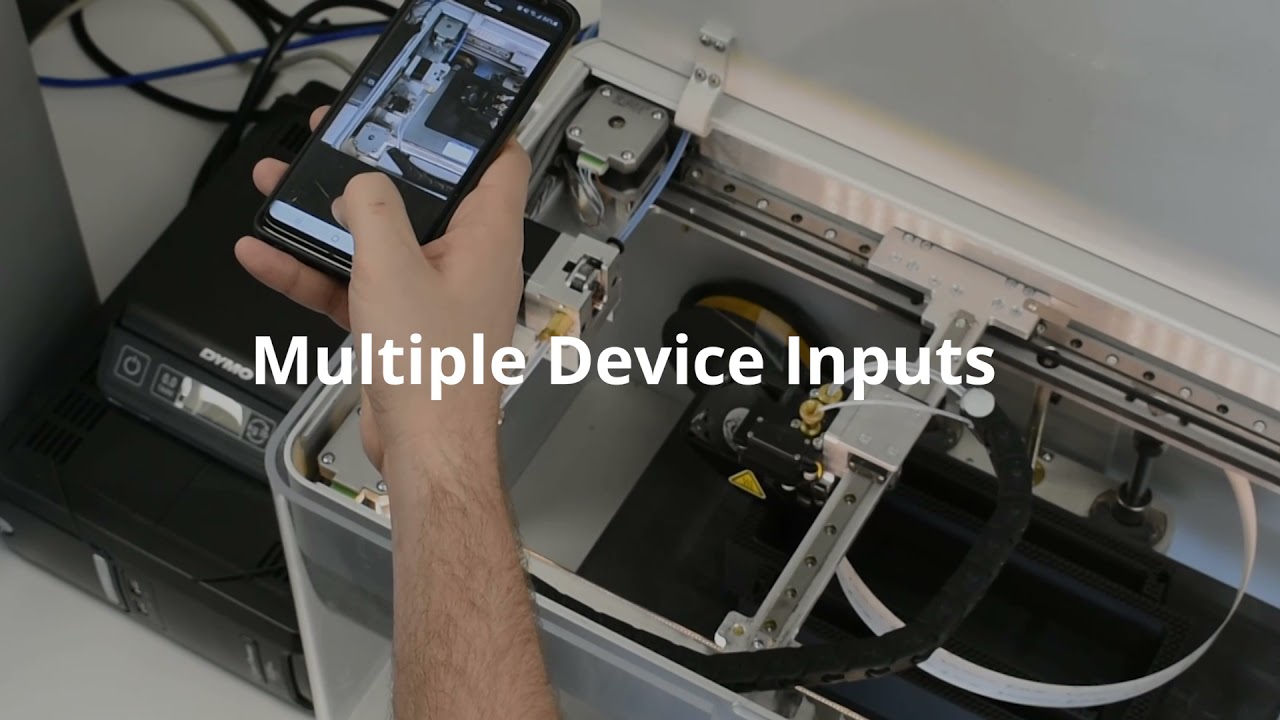

Mobile, Fixed or Robotic mounted imaging devices

Multi-Format Vision System or MVS is part mobile based and part server based application.

The system allows an operator equipped with a mobile device to acquire images of a select area to be inspected and sends that image to a server, where the AISTG Vision Studio passes it through vision based Deep Learning and traditional Machine Vision analysis software.

Once analyzed the system sends back the results to the mobile device. The whole process takes on average less than 1 second to complete.

This processing system is not limited to mobile devices. Fixed cameras and robot mounted cameras can provide images as well.

Deep Learning

This software uses state of the art machine learning algorithms developed for the variability found in vision applications to identify unique elements within the inspection. MVS can use both fixed cameras and/or mobile devices for image acquisition. Other systems can only use one or the other. MVS processes all images on premises, no Internet or cloud required. Therefore, no need to break a firewall to do image analysis

Communication

The system is localized and requires no internet connectivity. The system can communicate through either manual interaction or via PLC. MVS has prebuilt PLC communication blocks. Integrating is simpler, because communications are already to go, so signaling/triggering an event is easy

Data

The user interface contains five configurable metatags, along with pass, fail, date, time and part data. Recipes, user verification, and reporting are available as a service. MVS has its own SQL database for image/ data storage, inquiry and analysis. Auditing and batch searching a database is far less labor intensive than searching individual file folders for incomplete data

Hardware

An Industrial PC as a server runs the deep learning software. Android devices are used for image acquisition. The MVS license is per site. MVS can communicate with any pre-existing image devices using GigE. Re-purpose equipment rather than waste.

Technical Data

Core Competencies

- Mobile vision inspections

- Works on multiple devices

- Adaptive for product variations

- Mobile vision inspections

- Uses deep learning algorithms

- Cost effective inspections

- no floor space foot print

Technical Specs

- Interface to standard Industrial Protocols like Profonet or Ethernet IP. Digital I/O, or direct to controller such as Stanley, Bosch or Atlas Copco.